Valve Seat Cracking Repair

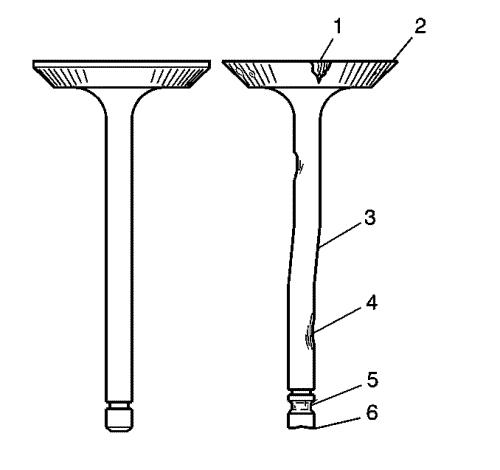

I'm about to use the www.LockNStitch.com repair system for a crack near one of the valve seats on a 346 flathead I'm rebuilding. The Lock N Stitch folks say that they don't recommend replacing valve seats or cylinder sleeves on a flathead, due to the small amount of metal in between, they say the pressure.

I'm about to use the repair system for a crack near one of the valve seats on a 346 flathead I'm rebuilding. The Lock N Stitch folks say that they don't recommend replacing valve seats or cylinder sleeves on a flathead, due to the small amount of metal in between, they say the pressure of an interference fit seat or sleeve can inevitably lead to more cracks. My machinist, of course, wants to put in new valve seats, which I suppose would certainly be advantageous with our unleaded gas. Just wonder if anyone else has an experienced opinion on this subject?

Depending on how thick your seats are and as long as they are not cracked, they should be able to reface them. The Unleaded fuel thing is way over blown. If you don't work an engine very hard like a marine engine or do a great deal of towing heavy loads you will not see any appreciable valve seat recession. In a classic car you will never use the car in the conditions or for a period of time long enough to harm your valve seats. Remember if you ask a machine shop if you need to buy something from them the will always answer in the affirmative. Good luck Fred P.

Pauldridge, Give David Black a call over at Travis Engine here in Austin (7th and Hidalgo.tell him I sent you). He's very sharp on this stuff.

I'll bet he'll say grind 'em and install the new stainless valves and go, but let me know. Also, do you have an extra set of the little splash pans that go under the intake manifold and over the lifter blocks? Mine are missing. I've seen them referred to in the shop manual. I can make a set, but I need some dimensions and the general shape. Give me a call when you can. Ken Karrer 1941 6227D coupe 512-626-7268.

Buddy, Thanks a lot, but really just a picture and some dimensions would be ok. I don't know how important they are, but figured Cadillac engineers had a reason for putting 'em in there. I can see the bolt holes in the lifter assy. Block and the area is pretty tight, so they must not be too big.

I'm in there (for the second time) because I had lifter noise and found that the oil lines hadn't been cleaned out as a part of the rebuild. I also replaced the upper aspect of the lifters (new plunger assys.), but I'm still getting more noise than I should. I did notice that some of the valve stem ends looked a bit short so I guess I'll check the 3' measurement when I'm in there this time. Sure don't want to take those heads off. Oil pressure is good @30 and I'm running SAE30wt. And cleaned out the lifter bodies.

Don't know what else it could be. Thanks again, Ken Karrer 1941 6227D coupe Thanks again, Ken Karrer 1941 6227D coupe. My '41 67 Series engine had cracks between two of the valve seats and cylinders. The machine shop used the lock'n'stitch method and also put sleeves and new seats in the two repaired areas.

The engine runs fine and there have been no problems so far (4 years). The car has not been on the road yet, but does get started and run to temp and around the property about once a month. I agree with Fred about not needing stainless seats in most collector cars that are babied. The main reason I elected to repair the block was to retain the matching number.

Harry, You mentioned Stainless Steel valve seats. Don't you actually mean Stellite Valve seats? This became the preferred material once unleaded fuel became the only choice available at the pump.

But leaving that aside, I think Fred is saying that Stainless Steel valves are probably not required for engines used in low stress application like most of our Flathead engines. This brings up an issue I'd like to hear a little more discussion about.

Namely, is it really required that SS valves be used on the intake side? I certainly understand the need on the Exhaust valve side of things when using unleaded fuel, but I wonder what others have experienced w/ just using the stock (non-SS) valve for the intakes. Now granted I'm a thrifty (reads 'cheap') fellow, but in my particular case, I rebuilt the engine about 35 years ago, and didn't use SS valves for either application. Of course back then non-leaded fuel was looked upon as something you had to use if you had a catalytic converter. But now, there is no choice so I'm wondering if those folks running unleaded fuel w/ stock intakes have actually experience any problem. Mark Lowery, CLC #25216. Mark, I probably should have said 'hardened' as opposed to 'stainless steel'.

I have always used the 'thrifty' approach for rebuilding these engines. I replace the valves that have a worn shoulder or are burnt with stock type valves and reface the serviceable ones. The only valve seats I have ever had to replace on five different engines were the cracked ones mentioned. I just finished the rebuild on my '37 and am hopeful of starting it for the first time today.

Everything is ready with the exception of wiring the electric fuel pump. Wish me luck. I hear people mention the ' lock & stitch ' system for fixing cracks in blocks. Back in the 50's i repaired several cracked blocks with a system that may be the same. What we would do was to drill 1/4' holes overlapping each other along the crack, tap the holes for fine thread bolts, install brass bolts with sealer in each hole, Grind off the bolts flush with the block, and use a center punch on each of the bolts to make them expand and that was the process for repairing the crack. When we reassembled the engine we would use block & radiator sealer in the cooling system as a final protection. If this is similar to the 'lock & stitch'system i would like to know?

Because brass expands faster then cast iron the fix works quite well. LeRoy, If interested, you can follow the link to their website on my original post. They have a number of videos showing the process, and, yes, it is a refined version of what you've done in the past.

Valve Seat Cracking Repair Kit

The main difference is some sort of special inverted thread which they claim actually pulls the drilled hole together, rather than expanding it, as a standard tap would do. And the threaded pins themselves are supposed to be very similar metal to the cast iron block, so no expansion differential issues to deal with. I've already done a couple of small repairs with this system. Really easy to use.

Now we'll see just how long it will hold up! Quote I hear people mention the ' lock & stitch ' system for fixing cracks in blocks. Back in the 50's i repaired several cracked blocks with a system that may be the same. What we would do was to drill 1/4' holes overlapping each other along the crack, tap the holes for fine thread bolts, install brass bolts with sealer in each hole, Grind off the bolts flush with the block, and use a center punch on each of the bolts to make them expand and that was the process for repairing the crack. When we reassembled the engine we would use block & radiator sealer in the cooling system as a final protection. If this is similar to the 'lock & stitch'system i would like to know?

Because brass expands faster then cast iron the fix works quite well. Well, I just completed the crack repair on my 346 using the LocknStitch pins.

These things are amazing. They use some sort of special 'inverted' thread pitch which supposedly pulls the metal together rather than spreading it.

The process is really simple, even for a ham-handed bonehead like me: 1) Drill a hole right along the crack with the supplied drill bit 2) Countersink the hole to accommodate the stepped head of the pin 3) Tap the hole with the tap provided 4) Dope up the pin and the hole with the sealant provided, then screw the pin in. Keep screwing on the hex head top until the top snaps off (by design) leaving the pin snugly in place 5) Using a die grinder, smooth down the protruding head of the pin to match the surrounding material (I used first a carbide metal grinding bit for the rough cut, followed by grinding stone to complete the job 6) repeat the same process, overlapping the first pin slightly to get full coverage of the crack My only mistake was following the locknstitch guy's suggestion to use a power drill for the tap. Wound up breaking off a tap in the very last hole. Miraculously was able to dig out the rest of the tap and complete with a larger diameter pin. I even used this to repair where the crack extended slightly into the cylinder itself. Now I'm going to tackle engine #2 which has cracks in three valve seats. I can see that this could easily be preformed on an engine in situ.

Without removing from the car, as long as the valve seat doesn't need replacement. Pics of the process below.

Model T Ford Forum: Cracked valve seat Cracked valve seat:: Cracked valve seat By on Sunday, November 03, 2013 - 07:59 pm: Is it possible to repair a crack starting at the valve seat area and leading to the side of the block in an exhaust port? It does not appear to be cracked all the way across.

New to the model T scene and any help would be appreciated. By on Sunday, November 03, 2013 - 08:40 pm: Yes,but quite possibly costly. Unless it is a rare block,might be easier to find another.

You can always rebuild it later. By on Sunday, November 03, 2013 - 08:59 pm: Yes it can be fixed by a machine shop. The crack can be pinned and a new seat installed.

I have to disagree with Uncle Jack, about $25 per crack including the seat. T blocks are famous for cracking in the center two exhaust seats from the valve to the outside of the block. Once repaired, problem gone.

By on Sunday, November 03, 2013 - 09:03 pm: Dale, Here are a bunch of ideas: Everything from run it to fix or junk it. My block has cracks with seats and it works fine. Jim By on Sunday, November 03, 2013 - 09:13 pm: Jack,it all depends on the machine shop. Around here,some of them think they have a license to steal. By on Sunday, November 03, 2013 - 09:15 pm: By on Monday, November 04, 2013 - 10:49 am: two engines i have replaced the seat with a hardened seat and poured in a bottle of a Micro head and block sealer. Both blocks have been running trouble free for 4 plus years. By on Tuesday, November 05, 2013 - 09:46 am: Dale: Yes we do this repair all the time as the Model T and Model A for that matter are prone to the exhaust seats cracking.

You need to find someone that does crack repair utilizing metal stitching. By on Wednesday, November 06, 2013 - 01:00 pm: Typically, with the type of hair-line cracks that usually occur in the #2 & #3 cylinder exhaust valve seats, if they point out in the direction of the exhaust manifold ports, all you generally have to do is install a seat and it will cure any potential issue. If the crack is big enough to catch your fingernail in, then maybe it needs to be stitched. My ACTUAL experiences: About ten years ago right after I bought my touring car, I did a valve job.

I reamed the valve guides oversize and re-ground 3-angle seats in with a Sioux Valve Seat Grinder. The block did not have hard seats and the center two exhaust valve seats had the 'typical' cracks mentioned above. At the time, I did not have the tool for installing hard seats in the block without pulling the engine, so I just left those seats just the way they were and didn't do anything about the hair line cracks. I installed new stainless valves, lapped them in, and timed the valves by piston position. I put roughly 15,000 miles on that car over the next couple years and had the head off to install new piston rings about four years later and pulled out those valves to examine what the seats looked like. The contact area between valve and seat was clean and polished and you had to look real close to see where the crack in the seat was.

If I didn't know it was there, I probably would never had seen it. There was no hint of discoloration or leakage near the crack. HOWEVER, at this time, I did have the tooling to properly install a hard seat and decided to do so at that time 'just in case'.

I have also seen quite a few of these 'typical' exhaust seat cracks on customers motors that I have had apart for one reason or another and no valve issue was noted previous to dis-assembly and no discoloration of signs of obvious leakage were present. I have a suspicion, that these types of cracks may have occurred early on in the life of some of these engines and probably only rarely ever got 'bad enough' to cause any issue. Your results may vary.

By on Thursday, November 07, 2013 - 12:55 am: Very interesting, I had those same crack's. Looked like they had been there a long time. Put seats in, but not really sure if I needed too now.

Install Valve Seats

By on Thursday, November 07, 2013 - 01:58 am: Here is one of the video's that Lock n Stitch put on Utube. These videos are in several parts so you have to find the following one.; This may be the same video:http: //.

One of the videos shows how to lock the repair. By on Thursday, November 07, 2013 - 12:00 pm: Quote: Very interesting, I had those same crack's. Looked like they had been there a long time.

Put seats in, but not really sure if I needed too now. Thanks Adam When the seats loosen up/fall out from the crack growing from heat you'll have to ask the same question over again. If we see a crack in an engine we fix it. There is no 'need to' it's 'Has To.' By on Thursday, November 07, 2013 - 12:20 pm: Not fixing cracks in a block no matter where they are at, shows a great LACK of Engine rebuilding knowledge!!!!!!!!!

Cobble, Cobble, Cobble!!!! By on Thursday, November 07, 2013 - 12:55 pm: O my 15 touring, I started to get water into the oil, and was told that crack like this was probably responsible. I have not yet pulled the head to check and don't plan to use it until fixed. I have another late 15 block to rebuild since the current one also has a big water jacket crack. By on Thursday, November 07, 2013 - 01:06 pm: 80% of all these 'typical' exhaust valve seat cracks that I have seen do not extend more than about 1/3 of the way out towards the exhaust manifold port. If they extend any further than that, I would recommend more of a repair than just installing a seat, but I rarely see them worse than that. The photo that J&M posted above is a far different story.

Any crack that extends towards or into a cylinder should be properly repaired. If the engine ever gets hot enough for one of these 'typical' cracks that extend in the direction of the manifold to 'grow' and cause a seat to get loose, the engine is likely to be so terribly overheated that a loose valve seat would be the most insignificant problem you would have. The cast iron block (under ordinary circumstances) is not flexible enough to allow the counterbore for that the seat to 'open up' and allow a seat to become loose.

With all this being said, I am not advocating that people don't have to do anything if they have valve seat cracks, or only have to put in a seat. What I am saying is that in most circumstances: If you are doing the rebuild yourself and, if that is all you are able to do, all you can afford to do, or all you are willing to do, then it is pretty likely that you probably won't have any further trouble. If you do have trouble, your T gets a trailer ride home and you fix it right at a later date, no big deal. HOWEVER, if you have it all apart and it is at the machine shop or re-builder, then of course, get it fixed!

By on Thursday, November 07, 2013 - 01:21 pm: Amazing!!!!! By on Thursday, November 07, 2013 - 01:34 pm: Dale Peterson: Check your freeze plugs to see if they are leaking. Believe it or not, I have seen instances of a freeze plug leaking and the antifreeze getting into the engine thru a valve cover that was poorly sealed at the top! It doesn't sound like much could get in that way, but it was enough to make the engine oil milky! Herm Kronke: Prattling on about 'not fixing cracks showing a lack of engine building knowledge Cobble Cobble, etc.' Herm, If someone was paying thousands of dollars to have an engine rebuilt, then yes, all cracks need to be properly repaired.

HOWEVER, if a hobbyist has the head off his T that otherwise runs fine and just happens to see one of these 'typical' cracks in an exhaust seat; Are you saying that the only rational thing he can do is pull his motor, strip it down and take it somewhere for repair or risk facing a catastrophic failure where his car will die a horrible death somewhere out in the middle of nowhere with buzzards circling overhead? By on Thursday, November 07, 2013 - 03:01 pm: Yes!

As you evidently don't know, cracks in blocks NEVER get better, they always get worse! Not fixing a known crack when first found will cost more in the long run. As J & M said, putting in a seat to stop a crack don't work. It is like using a big Cork as a cure for Diarrhea! And every body knows a Model T will never boil. And the Buzzards would only come in to effect from the owner shooting him self in the head from not repairing cracks.

Is it possible to repair a crack starting at the valve seat area and leading to the side of the block in an exhaust port? It does not appear to be cracked all the way across. 'END QUOTE' You leave a crack go in an exhaust port, and you may not be left with anything to fix. But who cares Adam, it won't cost use anything! By on Thursday, November 07, 2013 - 11:35 pm: I usually keep around 50 blocks on hand so I don't ever repair one, I just grab another one off the pile. The only time I would consider spending any time or money on a cracked block would be on a VERY EARLY one.

A little off the subject of repairing blocks it seems that 26 blocks are very popular any more. I have one guy take five 26 blocks and another took three.

Many others have taken one or two 26 block. While moving some blocks inside the shop today I thought why am I keeping so many blocks, I seldom rebuild one any more! Posting is currently disabled in this topic. For more information.